Why are Wire Gauge Charts & Tables Important?

If it is fixed properly in the slot (not hole), this is the exact gauge size (printed on that specific slot) of the wire. To use the wire gauge tool to find the suitable gauge size for a particular wire, simply remove the outer insulation and insert the wire conductor in the wire gauge slot one by one. It is a small circular shaped disc where different but common numbers are printed on it in accordance with the specific slots and holes.

If you are on the job site and need to know the wire size gauge for the particular load, one of the quick solutions is to use the handy device known as wire gauge tool.

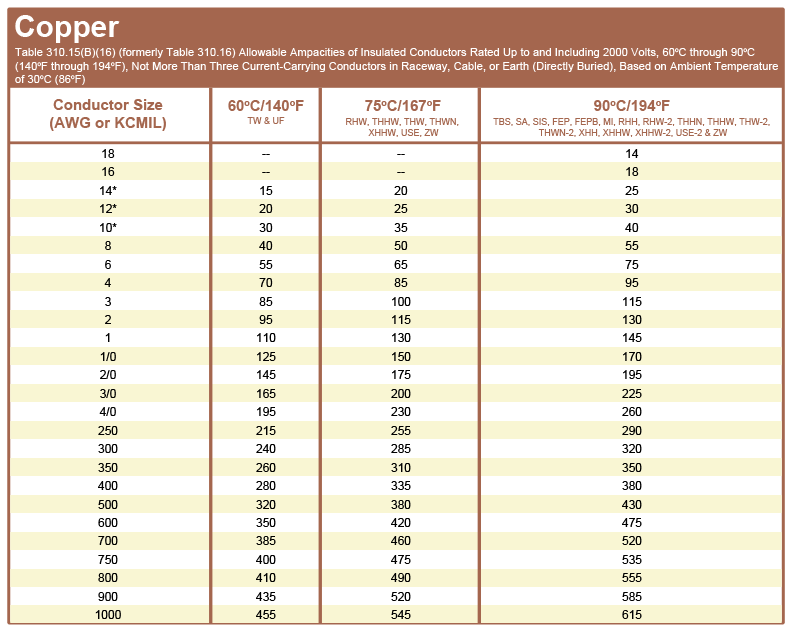

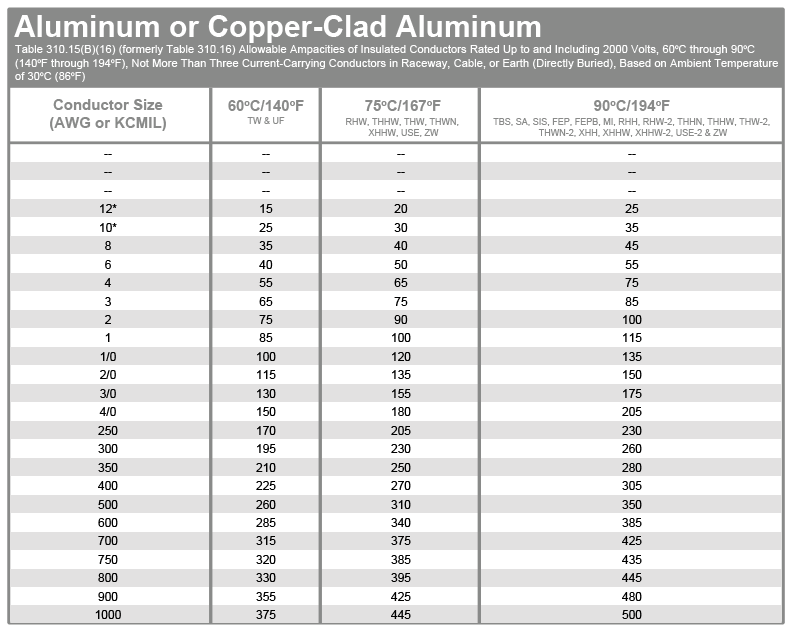

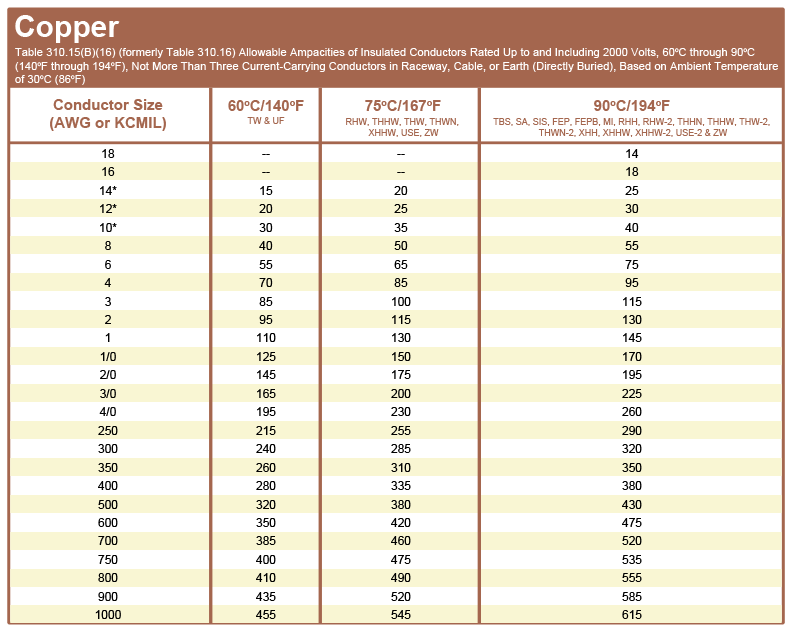

AWG/SWG to mm/mm 2, inch/inch 2 & kcmil Calculator & Conversion. Standard Wire Gauge “SWG” Calculator – SWG Size Chart & Table. American Wire Gauge “AWG” Calculator – AWG Size Chart & Table. Good to know: The American Wire Gauge (AWG) is also known as B and S Gauge (Brown & Sharpe Gauge). the higher the AWG size, the lower the ampacity and vise versa. In short, the ampacity is inversely proportional to the size of AWG integers (from 0000AWG to 40AWG) e.g. For example, the 14AWG size is a suitable wire for a 15Amp circuit breaker, whereas the 8AWG size is most appropriate for 40Amps of circuit breakers and load points. One thing should be noted about the AWG that the larger the integer, the smaller the thickness and diameter of wire. One of the most important roles of American Wire Gauge is to measure the current carrying capacity in Amps of wire (aka Wire Ampacity = The amount of maximum current that a conductor can carry continuously without exceeding its temperature rating. To purchase GHL Hook up Wire, Click HERE.The AWG is used to exactly measure the diameter of a particular conductor (such as solid, stranded, round and non-ferrous (alloys or metals that do not contain any appreciable amounts of iron) materials e.g. A 4% loss however is not recommended by DC Thermal and will result in less than desirable results with our heaters. You can go twice the distance where a 4% loss is acceptable. An example would be: A 12 volt heater, pulling 40 Amps, using a 10 gauge wire, could be ran a maximum of 2.8 feet. The numbers represent the maximum number of feet that wire can be ran without exceeding a 2 % loss. See the chart below to determine the maximum run with each gauge wire at a specific voltage. For example, a 1V drop from 12V causes 10 times the power loss of 1V drop from 120V. Wire must not be sized merely for the ampacity, because there is less tolerance for voltage drop (except for very short runs). In low voltage systems (12, 24, 36 and 48VDC) the overriding concern is power loss. Wire size in Direct Current is VERY important. A battery that is required to operate continuously at 0 degrees F will provide about 60% of its capacity. To function properly, these heaters must be wired with the proper size wire, and grounded properly, this cannot be stressed enough.īattery performance is dramatically reduced in low temperatures as well. Undersized wire is the single biggest mistake made when installing our heaters. Proper wire size is absolutely critical to insure that your heater works properly.

0 kommentar(er)

0 kommentar(er)